[color=hsl(0,0%,0%)]The future of car lighting in India is not just brighter, it’s smarter and more sustainable. Salvatore Blanco, Chief Technology Officer (CTO) of Marelli Motherson Lighting India, says Indian consumers, driven by a growing middle class and young population, are willing to pay for advanced technologies, prompting OEMs to introduce features already seen in China and speed up their time-to-market. Blanco explains how technologies like Adaptive Driving Beam (ADB) are changing the way we drive. From glare-free high beams that automatically adjust to traffic, to micro-LED systems delivering high-definition lighting, pushing the boundaries of safety, style, and efficiency. “We are expanding our production in India while focusing on energy-efficient, lightweight lighting made with recycled materials, including 100 per cent recycled aluminium in our LED modules,” he adds in conversation is with Utkarsh Agarwal, Editorial Lead of BW Auto World.

[color=hsl(0,0%,0%)]Q. For someone who may not know, could you explain in simple terms what Adaptive Driving Beam (ADB) technology is and why it matters for drivers?

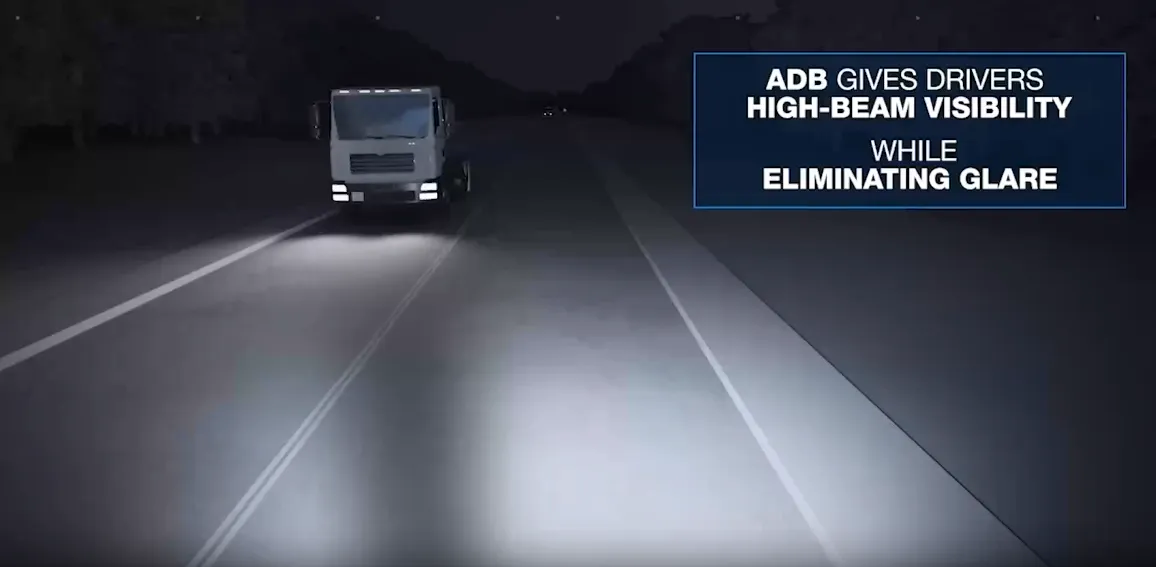

[color=hsl(0,0%,0%)]Adaptive Driving Beam (ADB) describes a vehicle front lighting technology that automatically adapts the light’s shape and performance to the surrounding conditions like traffic, landscape or weather. The most important ADB function is the so-called glare-free high beam. There are also other adaptive functions such as dynamic curve light adapting the light shape to the course of the road or adaptive adverse weather light. Yet, glare-free high beam has become synonymous with the entire ADB technology. It means that headlamps equipped with ADB can operate in high beam mode providing optimum visibility without dazzling others.

[color=hsl(0,0%,0%)]

[color=hsl(0,0%,0%)]The automatic light adaptation is carried out based on a camera data. When the camera, positioned on the windshield behind the mirror - area that must be kept cleaned - detects an approaching or preceding vehicle, it sends a signal to the headlamp to dim the light in the area of the detected object mostly by switching off or dimming the respective LED. This creates a gap in the light cone, a partial “shadow” by the lamp, preventing the oncoming vehicle from being dazzled and ensuring the driver excellent all-round visibility.

[color=hsl(0,0%,0%)]Q. How does ADB improve safety compared to regular headlights? And how is Marelli adapting ADB for Indian roads and driving conditions?

[color=hsl(0,0%,0%)]Several studies show that ADB significantly enhances the detection of vehicles ahead or approaching. This greatly improves reaction time and reduces the number of collisions. One challenge for ADB in India will be to equip cars with cameras that are sensitive to darkness or sensors, as there are many vehicles without lights on the roads, as well as pedestrians and animals.

[color=hsl(0,0%,0%)]

[color=hsl(0,0%,0%)]As ADB functions are based on camera detection, they are better able to detect oncoming or preceding traffic when it is well lit. The challenge is therefore to use cameras that are sensitive enough to detect these objects, whether vehicles or living beings, along the roads, even if they are not illuminated. This ensures that the lights are dimmed accordingly, improving safety and promoting the well-being of all road users.

[color=hsl(0,0%,0%)]Q. What challenges do you face when bringing advanced technologies like ADB to cost-sensitive markets like India?

[color=hsl(0,0%,0%)]The question partly contains its own answer. The main challenge is to combine both technology and cost efficiency. We can achieve this in a most efficient way by using standard and affordable ADB solutions rather than tailored ones.

[color=hsl(0,0%,0%)]Q. How closely do you work with OEMs when developing advanced lighting technologies? Can you share examples of recent collaborations with carmakers on ADB or other lighting solutions?

[color=hsl(0,0%,0%)]We work closely with OEMs to co-create lighting technologies, and in this process, we need to meet consumer preferences and to comply with local legal standards in each region. In addition, legal requirements, which differ from market to market, must always be taken into account. [color=hsl(0,0%,0%)]We work closely with OEMs to co-create lighting technologies, and in this process, we need to meet consumer preferences and to comply with local legal standards in each region. In addition, legal requirements, which differ from market to market, must always be taken into account.

[color=hsl(0,0%,0%)]Leading European OEMs now sell ADB lighting systems as standard, and we co-created this technology with many of our customer. The technology has evolved from standard LED solutions (initially mechanical, then electronic) through digital micro-mirror light to micro-LED-based technologies. Our recent developments relate to micro-LED ADB solutions, as these are even more precise than conventional LED-based systems and provide further benefits.

[color=hsl(0,0%,0%)]Q. How do OEM demands differ across markets like India, Europe, and Asia?

[color=hsl(0,0%,0%)]There are three factors that OEMs in different regions handle differently: performance, style, and fun. While performance and design/style are most important for European OEMs, Asian OEMs place a similar emphasis on the fun factor that the lighting must deliver. These varied demands are based on different realities, including affordability, road conditions, and environmental factors.

[color=hsl(0,0%,0%)]External lighting must cope with adverse weather conditions such as frequent fog, rain, and dust, which affect visibility. In India, the need to adapt to these adverse conditions - while prioritising performance and style due to the desire for brand recognition - plays a significant role. Although the entertainment factor may remain less important than in China, it is expected to gain some traction in the market.

[color=hsl(0,0%,0%)]In addition, as mentioned, legal regulations differ from market to market and are one of the main challenges. For example, while in Europe, lighting standards for headlamps, tail lamps, and signaling devices are stringently regulated by law. In India, there is an increasing alignment with international standards, but their enforcement varies. [color=hsl(0,0%,0%)]In addition, as mentioned, legal regulations differ from market to market and are one of the main challenges. For example, while in Europe, lighting standards for headlamps, tail lamps, and signaling devices are stringently regulated by law. In India, there is an increasing alignment with international standards, but their enforcement varies.

[color=hsl(0,0%,0%)]With a rising middle class and a growing young population, Indian consumers are willing to pay more for better technologies. OEMs are demanding features that are being introduced in cars in China. Indian OEMs are also pushing for shorter time-to-market due to the frequent introduction of new technologies.

[color=hsl(0,0%,0%)]Q. What role does local development and production in India play in your strategy?

[color=hsl(0,0%,0%)]Local development in India is very important for Marelli. We currently operate five lighting production plants in India: three in Pune, one in Sanand and one in Bawal. In addition, our Engineering (R&D) and technical centers are located in Gurgaon, Bengaluru and Pune employing over 1,000 engineers focused to a significant part on the lighting business, which we operate in India through our Joint Venture with Motherson called Marelli Motherson Lighting.

[color=hsl(0,0%,0%)]We are planning to further expand our production capacity in India. Establishing a tool shop in Noida in 2021 was an important step in this direction. This young facility enables us for example to produce by ourselves injection tools for lighting components for the domestic market – tools that we previously imported – thereby further improving local capabilities.

[color=hsl(0,0%,0%)]Q. What role does India play in Marelli’s global R&D network and how much do you invest?

[color=hsl(0,0%,0%)]Our approach is 'local for global.' Our R&D team in India contributes to advanced electronic systems including systems, hardware, mechanics, optics, software, and validation across all Marelli businesses worldwide. The team is actively developing and contributing to many Marelli projects globally. Besides India, we support Japan, EMEA, North and Latin America regions.

[color=hsl(0,0%,0%)]Q. How do you see software and electronics changing the way lighting systems are designed?

[color=hsl(0,0%,0%)]All state-of-the-art lighting systems are based on electronics - either using electronic control units (ECUs) within the lamps, or, according to the latest approach, moving electronics out of the lamp to the zonal computer. In all types of cars, the electric-electronic (EE) lighting control system remains key to improving vehicle safety and the driving experience. Today, the system also enables new features alongside conventional headlights and taillights. From single electronic control units (ECUs) to centralised domain control units (DCUs) on the path to cloud computing, Marelli Lighting supports this significant transition phase with the next generation of lighting ECUs.

[color=hsl(0,0%,0%)]

[color=hsl(0,0%,0%)]We provide customised, scalable solutions, including the option to separate hardware and software into different domains to meet the needs of our customers at whatever stage they are in their transition to software-defined vehicles.

[color=hsl(0,0%,0%)]Q. Sustainability is a big focus in the auto industry, how is Marelli addressing this in lighting solutions?

[color=hsl(0,0%,0%)]For our products, the greatest potential in lighting lies in enhancing energy efficiency by reducing power consumption and minimising weight. At the same time, our production processes must align with sustainability goals, since every product is only as sustainable as the way it is made. For this reason, we already use recycled materials for many components in our products.

[color=hsl(0,0%,0%)]A prime example is the cooling bodies for our LED modules, which are often made from 100 per cent recycled aluminum. Ultimately, the successful implementation of a sustainable approach will depend on collaborating with our customers.

[color=hsl(0,0%,0%)]Q. With EVs and connected cars growing, how is lighting evolving to match these changes?

[color=hsl(0,0%,0%)]Whether electric or conventional, cars need lighting. Electrification is likely to drive the development of exterior lighting toward greater efficiency in terms of power consumption and reduced weight. At the same time, the role of exterior lighting is expanding, as electrification offers new opportunities for innovation. Illuminated front panels are a good example of this. As a result, lighting may increasingly take on additional communication functions.

[color=hsl(0,0%,0%)]

[color=hsl(0,0%,0%)]Q. Apart from ADB, what new lighting technologies or concepts is Marelli working on?

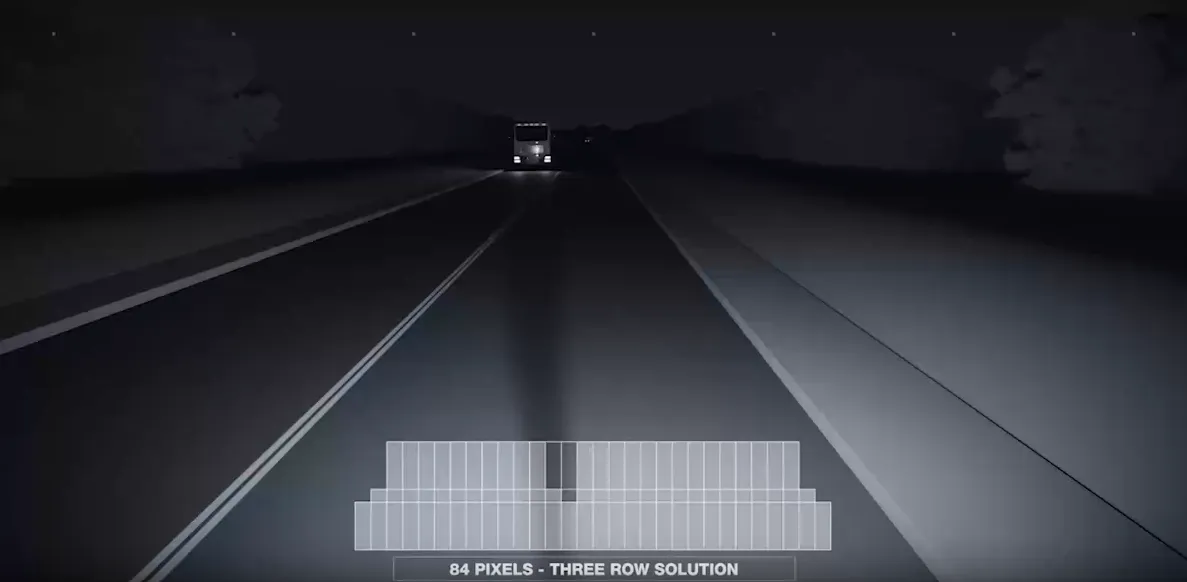

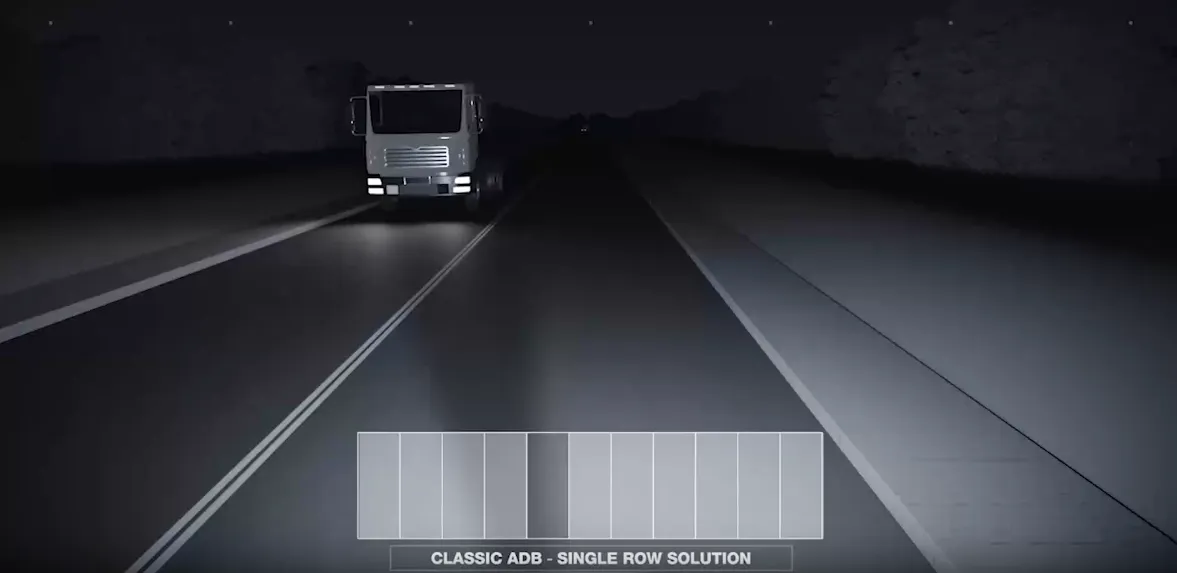

[color=hsl(0,0%,0%)]Introducing ADB represented a significant milestone. Numerous technologies are now employed to optimise its functionality. A recent example includes the use of micro-LED light sources instead of conventional LEDs, which allows for more precise modulation of light patterns and assists the driver with additional ground projections in their field of view, advancing high-definition lighting.

[color=hsl(0,0%,0%)]Just for comparison, our series micro-LED headlamps, currently use up to 25,000 tiny micro-LEDs per lamp, mounted in our in-house h-Digi microLED modules. In conventional LED headlamps, the number of LEDs and light segments ranges from 12 to 84 – in one, two or three rows – ensuring a reliable ADB illumination. Further new lighting technologies, in addition to above mentioned illuminated front panels are static and dynamic near-field ground projections for signaling purposes that are gaining increasing importance to improve safety, enhance brand identity, and enabling new ways of communication.

[color=hsl(0,0%,0%)]Q. Are you also looking at innovations beyond lighting? for example, in sensors or integration with ADAS.

[color=hsl(0,0%,0%)]At Marelli, we are pioneering the integration of advanced sensor technologies within our lighting products - specifically across vehicle modules such as the front, back, grille, and roof. This initiative is crucial for supporting the future of Advanced Driver Assistance Systems (ADAS) and autonomous driving features.

[color=hsl(0,0%,0%)]One of our primary strategies involves relocating most sensors toward the corners of the vehicle. This positioning is essential to achieve the optimal field of view (FOV). We are incorporating a range of sensor technologies, including RADAR, LiDAR, cameras, and far infrared (FIR) cameras. Additionally, we are exploring the potential of embedding zone control units (ZCUs) in lamps to facilitate low-latency operations and sensor prefusion.

[color=hsl(0,0%,0%)]

[color=hsl(0,0%,0%)]Our 'Smart Corner' solution maintains vehicle style while integrating pre-calibrated sensors, simplifying vehicle architecture. This approach leads to easier manufacturing, reduced installation costs, and quick software calibration. By embedding sensors in lamps and grilles, including efficient lens cleaning and heating, we offer cost savings through shared components, and centralise sensors in protected areas to enhance styling and sensor display. This strategy boosts vehicle functionality, cost efficiency, and manufacturing simplicity, aligning with Marelli's commitment to innovation and excellence.

[color=hsl(0,0%,0%)]Q. What does Marelli’s roadmap look like for the next few years in India?

[color=hsl(0,0%,0%)]Marelli is growing in India much faster than the Indian market. We plan to significantly increase our revenue in the next years.

[color=hsl(0,0%,0%)]Q. What big trends in automotive lighting do you see shaping the industry in the next 5-10 years?

[color=hsl(0,0%,0%)]The major trends in lighting involve software-defined systems that incorporate artificial intelligence and sensors. In the next 5 to 10 years, state-of-the-art headlamps will offer capabilities such as 3D mapping and adaptive lighting, thanks to advancements in sensors and sophisticated digital lighting technologies. These future developments promise additional features like improved environmental awareness and innovative design options. Furthermore, micro and nano optic technologies provide new possibilities for creative designs in both front and rear lighting.

[color=hsl(0,0%,0%)]Q. Finally, what excites you most about the future of automotive technology?

[color=hsl(0,0%,0%)]We know for certain that many innovations are on the horizon. Some of the directions in which technology is moving are already visible, but we are also aware that many developments remain unseen. It’s like an empty book that all of us in the automotive industry can help to write. We’re not just talking about evolution, but in some cases, about real revolution. We need to create new ideas, new words, new languages… |